PRESS BRAKE & POWER PRESS SAFEGUARDING & RETROFIT SOLUTIONS

Press Brake Guarding Systems: (ANSI B11.3 Compliant)

LAZER SAFE

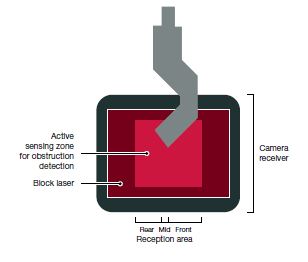

- This close proximity AOPD device allows the operator unrestricted access to the point of operation for increased productivity.

- The Lazer Safe System is PLe and Category 4 compliant.

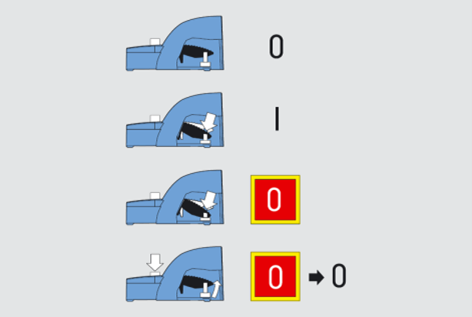

- If an obstruction is detected, the beam movement is stopped so that the punch cannot make contact with the obstruction

- As the tools close, the laser beam is muted just above the work piece, triggering a deceleration to stop pressing speed, while top laser continues to provide protection until the tools enter the bending position of the stroke.

LIGHT CURTAIN SYSTEMS

- This variation of the traditional guarding device allows for teachable beam blanking that can change cycle per cycle of the press brake resulting in the ability to make larger parts with flanges in different planes in a single handling.

- Paragon Industrial Controls machine specific interface features a stroke stop function which stops the ram at mute-point so small parts can be held inside the guarding area during bending

- PICI “Swing-Away” brackets are designed for easy tool changes and make alignment simple and easy to maintain.

STAMPING PRESS SYSTEMS

(ANSI B11.1 & B11.2 Compliant)

Paragon Industrial Controls, Inc.’s creative solutions to Stamping Press safeguarding provides a safe and productive solution for these machines. ANSI B11.3 Compliant Press Controls, Application Specific Operator Interfaces, Name Brand Safety Devices, and Robust Bracketing are standard. Versatility, durability, and productivity along with safety are the primary features of our distinctive design customized to your application.

Our system uses only the highest quality light curtains combined with Paragon Industrial Controls, Inc. unique Swing-Away brackets with key-locked removable bars. Light Curtain alignment problems are non-existent!

Our highly trained staff will integrate the safety related devices correctly into an OSHA compliant press control. The result: the most safe and versatile press guarding system available today!

TONNAGE MONITORS

The Toledo Integrated Systems Quik-Learn Automatic Tonnage Monitor digitally displays the working press tonnage for the left and right sides of the press. This unit also displays Total tonnage and the % deviation from the target tonnage.

The Toledo Integrated Systems PWi PressWatch Production Monitor is a four channel, cost effective full-featured monitor that interfaces with load sensors to provide force measurement for press protection and quality control. Each channel and the total is displayed on high-visibility 5-Digit LED displays. The LCD graphic display provides a user-friendly menu system.

The Toledo Integrated Systems Press Attendant is a press automation and monitoring package. It combines tonnage monitoring, die protection, programmable limit switches, brake monitoring, motion detection and more into ONE encoder based system. This all-in-one package will help protect your investment and reduce downtime

The Toledo Integrated Systems Co-Pilot is a press automation package with resolver-based signatures. It integrates tonnage monitoring, die protection, programmable limit switches, brake monitoring, motion detection, signatures with enveloping and more into ONE resolver-based system! The display is a 6.5″ color screen. Signatures and press information can clearly be viewed from many angles.

Many more systems to choose from can be found at www.ttoledo.com.

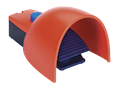

3-Position Safety Foot Switch

- ANSI B11.3.6.3.4.7 requires when using safe speed (a ram speed of 10 mm/sec (0.39 in/sec]) as a safeguarding method, a three-position hold-to-run control shall be used.

- Extensive accident prevention research has shown that in the event of pain and/or distress, the foot is frequently not removed from the foot pedal.

- Weight is often shifted forward and pressure on the foot pedal is increased rather than removed.

Recognizing this, the safety foot switch features a 3-stage operation. It is designed to stop hazardous movements in machinery whether released or fully depressed in an emergency situation